Type: Rice Bran Oil Pretreatment Machinery, Rice Bran Extrusion Processing Plant, Rice Bran Oil Expeller

Productive Capacity: 30-3000 Tons per day

Rice Bran Oil Pretreatment Processing Material: Rice Bran

Major Equipment of Rice Bran Oil Pretreatment line: Vibrating Screen, Magnetic Separator, Softening Machine(Conditioner), and Extrusion Machine (rice bran oil extruder machine).

Application:

Rice bran oil pre-pressing section has very high efficiency in rice bran extrusion process, Also it is the granulation for preparation of Rice Bran Oil Extraction Process.

The rice bran oil pretreatment process mainly consists of cleaning section, rice bran and tips separation machine, rice bran softening and conditioner and rice bran extrusion machine. In addition, this patented production line of rice bran pretreatment and extrusion machinery adopts the reasonable designs. It can make high efficient extrusion for rice bran. What’s more, the rice bran oil extrusion pretreatment line is featured by high quality rice bran extrusion effect, lower manpower and production cost, small floor space, low power consumption, etc.

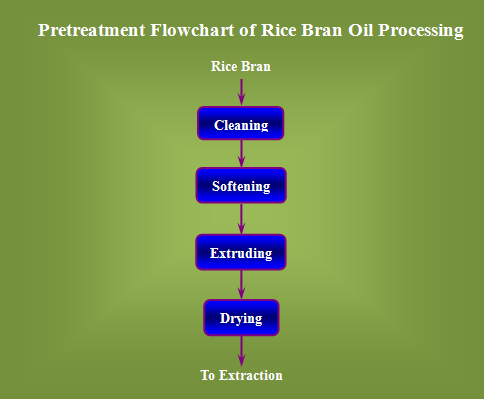

Process flow chat of Rice Bran Oil Pretreatment & Extrusion Processing introduces as follows: Rice bran cleaning →softening →extrusion →drying →to extraction workshop

Cleaning Process:

Adopting the magnetic separator to remove iron impurities, rice bran and fine broken rice, then separation sieve to separate rice bran and fine broken rice.

Rice Bran Extrusion Process:

The Rice Bran Oil Extrusion Machine can both improve the yield of rice bran oil and reduce the consumption. On the one hand, rice bran oil extruder machine can make the lipase in rice bran to be passivated under the high temperature and pressure condition, then to prevent the rice bran oil from rancidity; On the other hand, rice bran oil extrusion puffing can make rice bran to be porous grain to increase the materials bulk density, and improve the permeability and extraction rate that the solvent reacts to the rice bran.

Rice Bran Drying Process:

The puffed rice bran contains about 12% water, but the best moisture for Rice Bran Oil Solvent Extraction Plant is 7%-9%. Therefore, there must be effective drying ways to achieve the best extracting moisture. The counter-current dryer can make water and temperature to meet with the following rice bran oil processing requirements quickly, meanwhile to improve the rice bran oil yield as well as oil quality.

Rice Bran Oil Pretreatment Machinery Craft Features:

1) To create a good production environment well;

2) To minimize the total fat loss, and increase rice bran oil yield and output, what’s more, to improve the quality of rice bran oil and cake meal;

3) Comprehensively to utilize impurities and offal;

4) Perfectly to match rice bran oil extraction production line, and design different cooking oil production processes according to different materials.

Certifications: