Type: 200-1000T/D Set of Rice Bran Oil Production Line, Rice Bran Oil Processing Machine, Rice Bran Oil Mill Plant

Productive Capacity: 200-1000 Tons per day

Raw Material: Rice Bran

Processing Flow: Rice Bran Oil Production Line includes Rice Bran Oil Pretreatment Machinery, Rice Bran Oil Solvent Extraction Plant, Rice Bran Oil Refining Machine.

Rice Bran Oil Pretreatment Machinery: Rice Bran-tips Separation Section; Rice Bran Softening And Conditioning Section; Rice Bran Extrusion Section.

Main Equipment: Magnetic Selector, Rice Bran-tips Separation Sieve, Elevator, Softening Conditioner, Cooker etc.

Rice Bran Oil Pretreatment Machine:

The rice bran will contain stones, soil, debris, etc. during rice processing. Therefore, these impurities need to be removed to obtain pure rice bran. The cleaned rice bran is then steamed and fried to adjust the temperature and moisture, and then sent to the puffing machine to turn it into a porous and soft structure, which is more conducive to the extraction of rice bran oil.

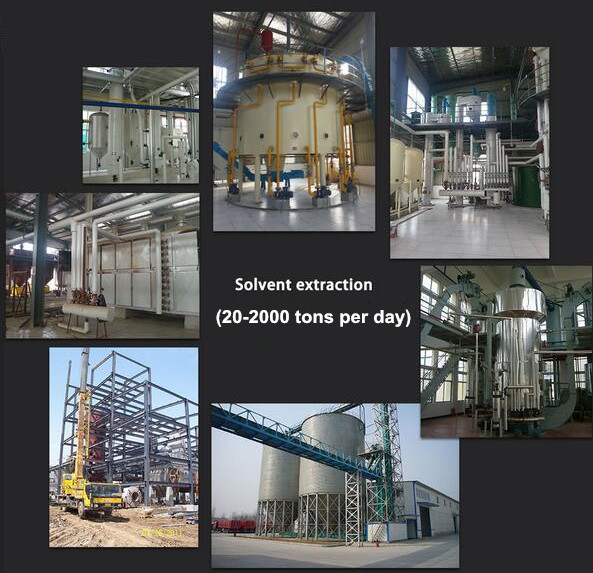

Rice Bran Oil Solvent Extraction Plant: Rice Bran Oil Solvent Extraction Section; Desolventizing And Toasting Section; Evaporation Section; Condensation Syetem.

Main Equipment: Rotocel/Loop/Towline Extractor, Desolventizer Toaster, Mixed Oil Evaporator etc.

Rice Bran Oil Solvent Extraction Machine:

The puffed rice bran can be sent to extraction equipment to get crude oil. Rice bran oil solvent extraction plant is the process that uses the principle of solid-liquid extraction, selects an organic solvent that can dissolve oil, and sprays and soaks rice bran to fully contact the oil, thereby extracting the oil from the oil. The rice bran oil solvent extraction plant to produce rice bran oil has the advantages of high oil yield, high economic benefits, and good meal quality.

The rice bran oil extraction process has high production efficiency and high degree of mechanization, and is suitable for large-scale rice bran oil production. However, the extracted crude rice bran oil contains various impurities and solvent residues during rice bran oil process, so the crude rice bran oil still needs to be refined and removed.

The Consume of Rice Bran Oil Solvent Extraction Plant:

(1) Solvent consume per ton material: ≤7kg/t

(2) Electric consume per ton material: 5kwh

(3) Sream consume per ton material: 350kg

(4) Water consume per ton material: 1.0 CBM

(5) Cycle of water per ton material: 35 CBM

Rice Bran Oil Refining Machine: Physical Deacidification And Deodorization Section; Rice Bran Oil Continuous Dewatering Section; Rice Bran Oil Decolorization And Filtering Section; Rice Bran Oil Crystallization And Maturing Section; Rice Bran Oil Dewaxing Section; Electric Control System.

Main Equipment: Filter Equipment, Deacidification Tower, Crystallization & Maturing Tank, Deodorization Tower, Crude Oil Tank, Decolorizing Tank etc.

Rice bran oil refining machine:

The rice bran oil refining process requires five main processes including degumming, deacidification, dehydration, decolorization, deodorization and dewaxing. The functions of these processes are as follows:

1. Degumming: Remove the peptidic impurities formed by the mixture of phospholipids, proteins, sugars, resins and other impurities in rice bran oil. These impurities are important factors that cause rice bran oil to become darker and turbid, and affect the storage properties of rice bran oil.

2. Deacidification: Excessive free fatty acid content in rice bran oil will produce pungent odor and affect the flavor of the oil. Free fatty acids themselves are catalysts for fats and phospholipids. The solubility of water in oils also increases with the increase of free fatty acids, so they need to be removed.

3. Decolorization: Decolorization can improve the color of rice bran oil and improve its appearance. In addition, it can also remove polycyclic aromatic hydrocarbons, pesticide residues and oxidative deterioration substances caused by pollution.

4. Deodorization: To remove “odor” from rice bran oil. Such as the natural flavor of oil, burnt smell, solvent smell, earthy smell generated during processing, etc. These flavors will affect the quality of oil. The deodorization process can be removed under high temperature and vacuum conditions with the help of steam distillation principle.

5. Dewaxing: Rice bran oil contains a small amount of rice bran wax. This wax is not absorbed by the human body and will dissolve in the oil when the temperature is high. When the temperature is low, it will solidify to affect the quality of the rice bran oil. Therefore, it needs to be cooled and crystallized through rice bran oil dewaxing process, and then the oil and wax are separated through plate and frame filter. The refined and dewaxed rice bran oil is the finished rice bran oil.

Applicable Oilseeds: Rice bran oil production machine is also suitable for other vegetable oilseeds, such as: Soybean, Sunflower seed, Rapeseed, Cottonseed, Peanut, Palm Kernel, Copra, etc.

Certifications: