Type: 1000-5000T/D Set of Rice Bran Oil Processing Plant, Rice Bran Oil Production Process, Rice Bran Oil Making Machine, Rice Bran Oil Project Cost

Productive Capacity of Rice Bran Oil Processing Plant: 1000-5000 Tons per day

Raw Material: Rice Bran

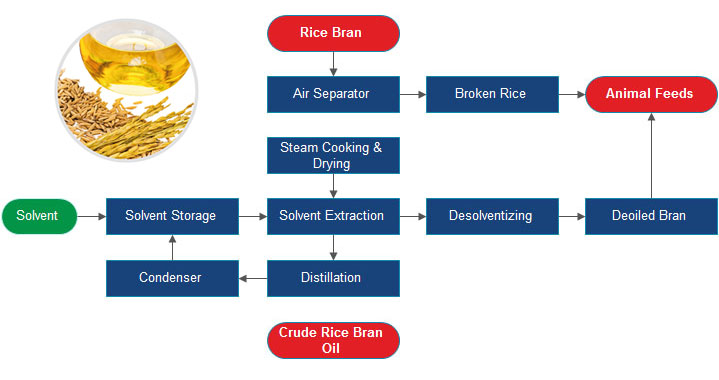

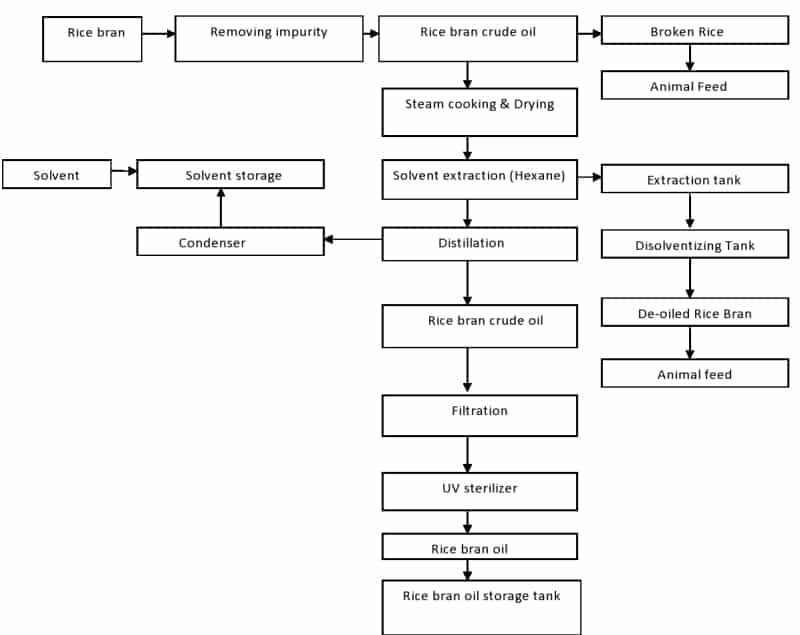

Processing Flow: Rice Bran Oil Pretreatment Process, Rice Bran Oil Solvent Extractinon Process, Rice Bran Oil Refining Machine.

Rice Bran Oil Pretreatment Process: Rice Bran-tips Separation Section; Rice Bran Softening And Conditioning Section; Rice Bran Extrusion Section.

Main Equipment: Magnetic Selector, Rice Bran-tips Separation Sieve, Elevator, Softening Conditioner, Cooker etc.

Rice bran oil production process – rice bran pretreatment section

1. The rice bran obtained during rice processing will contain a small amount of impurities, so the rice bran and broken rice must be separated with a bran separation screen to obtain pure rice bran.

2. Then, the rice bran enters the conditioning pot, and a small amount of steam (about 2% of the raw material amount) is introduced for steaming and frying.

3. Then, it enters the extruder and uses the difference in air pressure to turn it into a porous and soft structure, which is conducive to subsequent rice bran oil extraction process.

4. Finally, the puffed rice bran enters the flat plate drying equipment for drying and cooling. The pretreated rice bran can be sent directly to the rice bran oil extraction plant for processing, or it can be stored first (it can be stored for about 1 week).

Rice Bran Oil Solvent Extraction Process: Solvent Extraction Section; Desolventizing And Toasting Section; Evaporation Section; Condensation Syetem

Main Equipment: Rotocel/Loop/Towline Extractor, Desolventizer Toaster, Mixed Oil Evaporator etc.

Rice bran oil production process flow – rice bran oil solvent extraction plant

rice-bran-oil-solvent-extraction-process

1. After the rice bran is pretreated, the puffed rice bran particles enter into rice bran oil solvent extraction machine. After the solvent n-hexane is sprayed, the oil in the rice bran will dissolve in the solvent to form a mixed oil. Then, the mixed oil is filtered through the screen, and the resulting relatively clean mixed oil will enter the mixed oil evaporation system.

2. Due to oil is almost non-volatile, solvent has a low boiling point and is easy to volatilize, the solvent is evaporated and steamed out through two evaporations and one stripping to obtain rice bran oil.

3. The wet meal filtered and separated by rice bran oil extractor contains a small amount of solvent, then water vapor is introduced into it to remove the solvent. The principle is the same as the mixed oil evaporation system.

4. The evaporated solvent will be cooled and recycled through the condensation recovery system, and then enters the solvent turnover tank to wait for use in the next production.

The Requirements for extraction material, steam, water, electricity etc.:

(1) Moisture of extraction material: 5-8%

(2) Temperature of extraction material: 50-55¡æ

(3) Oil content of extraction cake: 14-18%

(4) Thickness of extraction cake: ≤13mm

(5) Powder degree of extraction material: ≤15% (30meshes)

(6) Steam: ≥ 0.6Mpa

(7) Solvent: National standard No.6 solvent oil

(8) Power electricity: 50Hz 3 x 380V ±10%

Lighting electricity: 50Hz 220V ±10%

(9) Temperature of supplement water: ≤25¡æ

Hardness: ≤10

(10) Volume of supplement water: 1-2m³/t raw material

(11) Temperature of recycle water: ≤32¡æ

Rice Brn Oil Refining Machine: Physical Deacidification And Deodorization Section; Rice Bran Oil Continuous Dewatering Section; Rice Bran Oil Decolorization And Filtering Section; Rice Bran Oil Crystallization And Maturing Section; Rice Bran Oil Dewaxing Section; Electric Control System.

Main Equipment: Filter Equipment, Deacidification Tower, Crystallization & Maturing Tank, Deodorization Tower, Crude Oil Tank, Decolorizing Tank etc.

Rice bran oil production process flow – rice bran oil refining and dewaxing process

1. Hydration degumming: Add a small amount of hot water to the crude rice bran oil (the amount of water added is about 1%-3% of the weight of the crude oil) to cause the water-soluble impurities to condense and precipitate, and then separate from rice bran oil.

2. Vacuum drying: Hydrated degumming oil may contain a small amount of water, and a continuous packing dehydrator needs to be used for dehydration before decolorization. The drying vacuum degree is about -0.09Mpa.

3. Adsorption and decolorization: The vacuum-dried rice bran oil is transferred into the decolorization tank, and is fully contacted with the adsorbent (white clay) under stirring. After completing the adsorption equilibrium, it is pumped into the blade filter by the oil pump for filtration after cooling, and the adsorbent is separated (white clay).

4. Deacidification: The decolorized oil is first heated by the oil-oil heat exchanger, and then heated by the heater to about 250°C, and then enters the deacidification tower. The deacidification tower is a structural packed tower. The oil is on the surface of the packing from the top under the action of gravity. It flows downward and fully contacts with the saturated steam injected from the bottom to achieve the purpose of stripping and deacidification.

5. Deodorization: The deodorization tower is also a structural packing tower. The deacidified oil flows downward from the top under the action of gravity on the packing surface, and fully contacts with the saturated steam injected from the bottom to achieve the purpose of stripping and deodorization.

6. Dewaxing: Rice bran oil contains a small amount of bran wax, which will affect the flavor of rice bran oil. When the temperature is high, rice bran wax will dissolve in the oil in a molecularly dispersed state. Therefore, the deodorized oil can be directly pumped into a condensation crystallization tank for cooling and crystallization, and then the uniformly crystallized oil is pumped into a plate and frame filter press for filtration. The refined rice bran oil will flow out and then be pumped into the finished oil tank, while the bran wax will remain on the filter cloth to achieve the purpose of oil and wax separation.

rice bran oil production line

Craft Features of Rice Bran Oil Manufacturing Plant:

1) Continuous alkali refining shortens the contact time between oil and lye, reduces grease oil saponification, lower oil refining consumption and improves efficiency;

2) Decolorization adopts technology of combing of premixing and steam mixing bleaching, which improves the bleaching efficiency, save consumption of bleaching clay, and it is simple and convenient to operate; and the negative pressure state avoids oxygen in the air from contacting with hot oil, thereby ensuring oil product quality, and inhibiting acid value to rise again and lowering peroxide value;

3) Deodorization adopts the new type continuous deodorization equipment which is applicable for plant oil deacidification and deodorization of oils high acid value and low-resin content. The actual production proves its most obvious advantages are strong deacidification ability, excellent hot bleaching effect, high refining rate (increase for 0.4/AV), steam economization, good oil quality and the like;

4) Henan Huatai rice bran oil production process has multiple heat exchanges, which makes full use of the heat energy system, effectively reduces steam consumption, and also has the advantages of adjustable production process, flexible operation, high automatic degree, environment sanitation and other advantages.

Certifications: