Rice Bran Oil Machine Specifications:

1. Low energy consumption

2. High oil yield and purity

3. Save solvent

4. High performance

Pretreatment and Press Process of Rice Bran Oil Machine:

Cleaning and separating—-steaming—-cooking—-pressing—-filter—-crude oil

Each Step Purpose of Rice Bran Oil Machine:

A. Cleaning and separating: Remove the broken rice and other impurities, that can guarantee the rice bran oil yield. This process mainly to remove the impurities like iron, sand, broken rice and others. If the impurities exist in the rice bran, it will affect the machines operation. And make the crude oil impure, then largely affect the rice bran oil refining process.

The cleaning method mainly includes screen and magnetic separation.

B. Steaming: In order to soften the crude fibre and conglomerate the protein, break the cell wall, small oil drip can gather into the big oil drip, so that the oi can be easily out. This process namely soften the rice bran, making the bran cooked. As the rice bran is low oil content and low moisture content, so it has to through steaming to adjust its moisture and temperature to a suitable level that can increase the rice bran elastic-plastic, break the cell wall and oil easily out when pressing.

Condition: rotate speed: 40

temperature:80~100°C

time:10 min

moisture:25~30%

C. Cooking: Lower the moisture in the rice bran, so that oil can be easily out. This process has the same purpose with steaming, aiming to make the oil out easily, the difference is just lower the moisture to 5~7%, to much water content will affect the rice bran oil quality.

Condition: stir constantly

temperature: 125°C

time: 20~30 min

moisture lower to:5~7%.

D. Pressing: This is the oil out process, the cooked rice bran will be sent to screw oil press machine through the screw conveyor. After pressing, we can get the crude rice bran oil.

Condition: temperature: 80~90°C

time: 3~5 min

E. Filter: Filter the crude oil with canvas or double layer cloth in the Plate-fram filter, control the temperature to 70°C, then the crude oil will be sent to the refining process.

Condition: temperature: 70°C

Refining Process of Rice Bran Oil Machine:

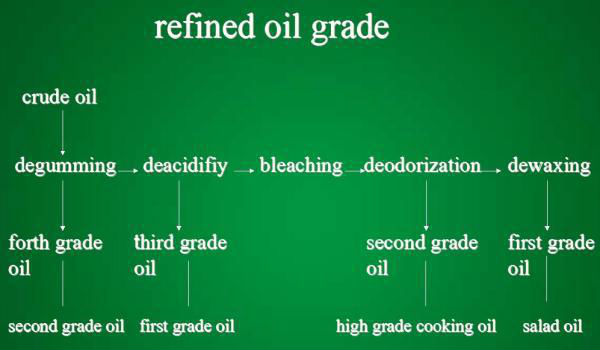

Crude oil—-degumming—-deacidification—-decoloring—-filter—-deodorizing—-fourth grade oil

Crude oil—-degumming—-deacidification—-decoloring—-filter—-deodorizing—-dewaxing—-degrease—-first grade oil

Introduction of the Complete Rice Bran Oil Processing:

A. First, send the crude oil into the mix reactor with certain quantity water and acid, after well blended send into the centrifugal separator and then separate the oil sediment.

B. Second, send into another mix reactor, adding certain concentration alkali and well neutralization reaction. Separate the soap stock through the centrifugal separator.

C. Third, wash the crude oil with light alkali and water, washing out the residual soap stock.

D. Then, send the oil into the bleaching tower, well blended with certain quantity clay, under the certain temperature, time, vacuum condition, the clay absorb the colorful substance and other impurities. Then separating the waste clay through the centrifugal separator.

E. At last, send the oil into deodorization tower, under the certain temperature and vacuum condition, deodorizing the oil through steam stripping. Then get the fourth grade oil.

Our Rice Bran Oil Machine Advantages and Price:

1. Some of our technology adopts Germany standard, and some equipment parts are imported.

2. Our stainless steel and carbon steel are all purchased directly from the steel factory. Our professional engineer will detect every time.so we can guarantee the quality.

3. All of our welding technicians have the employment certificates. They are good at it.

4. We provide installation and professional training on-site service for customers.

5. We supply the best service to our customer, if there is any technology problem, we will transfer it to our customer.

6. Rice bran oil machine price is determined by customers’ demands. We can make a professional design and proposal according to your actual situation.

Huatai Rice Bran Oil Equipment Return on Investment (ROI) Analysis:

ROI analysis involves multiple variables. Specific figures need to be adjusted according to your actual situation (scale, location, raw material costs, etc.).

-

Investment Cost Estimation (taking 100TPD Rice Bran Oil Processing Plant as an example)

Equipment investment: Includes a complete rice bran oil production line for stabilization treatment (extrusion), pretreatment, extraction, and refining (four stages: degumming, deacidification, decolorization, and deodorization). Huatai rice bran oil equipment price is estimated to be between 3 million and 6 million RMB, depending on the degree of automation and configuration.

Factory building and infrastructure: Approximately 1 million to 2 million RMB.

Installation, commissioning, and working capital: Approximately 1 million to 1.5 million RMB.

Total investment estimate: Approximately 5 million to 9.5 million RMB.

-

Operating Costs and Revenue Analysis (annual basis, rough estimate)

Main assumptions:

300 operating days per year, processing 100 tons of rice bran per day.

Rice bran purchase price: Approximately 2,000 RMB/ton (prices fluctuate significantly).

Crude oil yield from rice bran: 14%-16% (assuming good stabilization treatment, taking the upper limit).

Crude oil refining rate: 85% (Grade 1 oil).

Rice bran meal yield: Approximately 80%, with high protein content, making it a high-quality feed.

Revenue:

Rice bran oil revenue: Annual production of Grade 1 oil is approximately 100 tons/day * 16% * 85% * 300 days ≈ 4,080 tons. The selling price of Grade 1 rice bran oil is approximately 10,000 – 12,000 RMB/ton, taking the median value of 11,000 RMB, the oil sales revenue is approximately 44.88 million RMB.

Rice bran meal revenue: Annual production of meal is approximately 100 tons/day * 80% * 300 days = 24,000 tons. The selling price is approximately 2,000 RMB/ton, so the meal sales revenue is approximately 48 million RMB. Total Revenue: Approximately 92.88 million RMB/year.

Cost Breakdown:

Raw Material Costs: 30,000 tons of rice bran * 2,000 RMB/ton = 60 million RMB.

Processing Costs (energy consumption, labor, auxiliary materials, packaging, depreciation, etc.): Approximately 800 – 1,200 RMB per ton of raw material; taking 1,000 RMB, the annual processing cost is 30 million RMB.

Total Costs: Approximately 90 million RMB/year.

Gross Profit Estimation:

Annual Gross Profit ≈ Total Revenue – Total Costs = 92.88 – 90 = Approximately 2.88 million RMB.

Note: This is a very simplified model. In reality, profits can be significantly increased through refined management, deep processing of by-products (such as gamma-oryzanol and calcium phytate), and brand premium. Meanwhile, fluctuations in rice bran and oil prices have a significant impact on profits.

-

ROI Calculation

Static Payback Period:

Annual Net Profit (assuming gross profit, before tax, etc.) ≈ 2.88 million RMB.

Taking the median total investment of 7.25 million RMB.

Static Payback Period = 7.25 / 2.88 ≈ 2.5 years.

Return on Investment (ROI):

Annual ROI = Annual Net Profit / Total Investment * 100% = 2.88 / 7.25 * 100% ≈ 39.7%.

Please note: The above calculations are highly simplified ideal models. Actual ROI is profoundly affected by the following factors:

Positive factors: Stable and controllable raw material supply chain, deep processing of by-products, branded oil sales, government subsidies for technological transformation or agricultural industrialization.

Risk factors: Drastic fluctuations in raw material prices, poor sales channels for finished oil products, fierce homogeneous competition, and unstable initial production rate and product quality.

Professional Suggestion:

Kindly please inform us your required daily capacity, raw material, covering space and related data, so that we can provide you professional equipment information and design rice bran oil production line for you. We will suggest economical and reasonable rice bran oil machine for you.